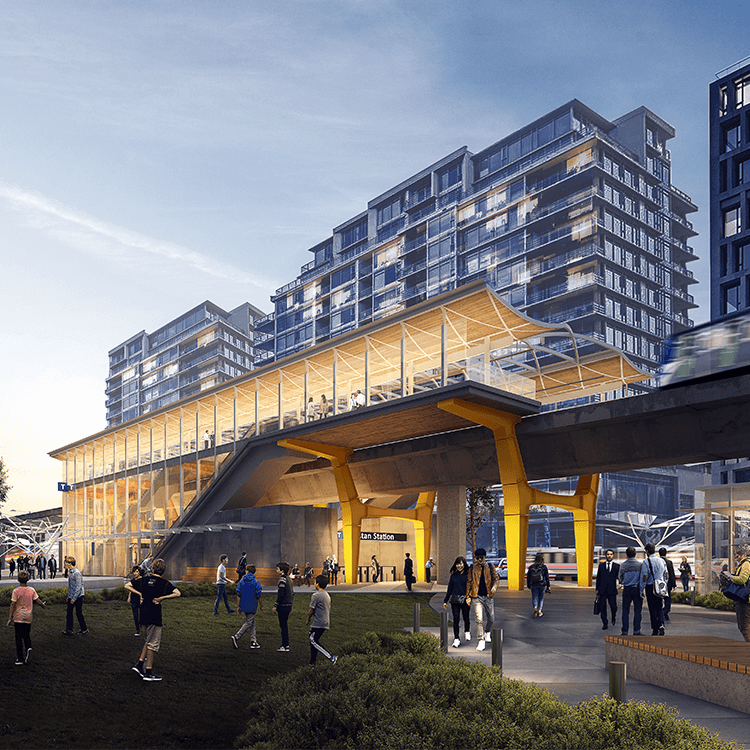

Southwest Library

Washington D.C.

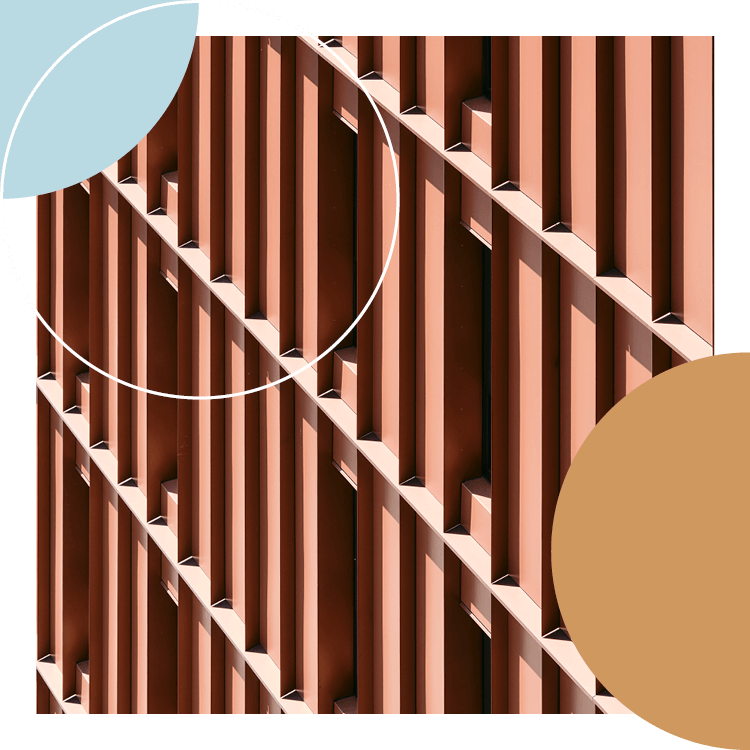

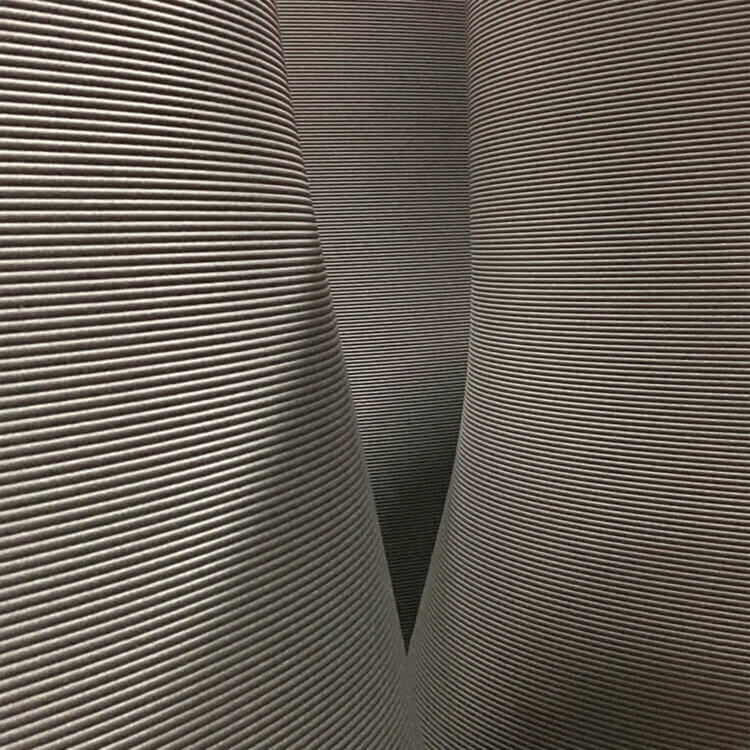

The newest library in the D.C. Public Library (DCPL) system has only been open since 2021, but it’s already an icon. Its most striking feature is its “folded plate” roof, which evokes the pages of open books and extends into the neighboring park.

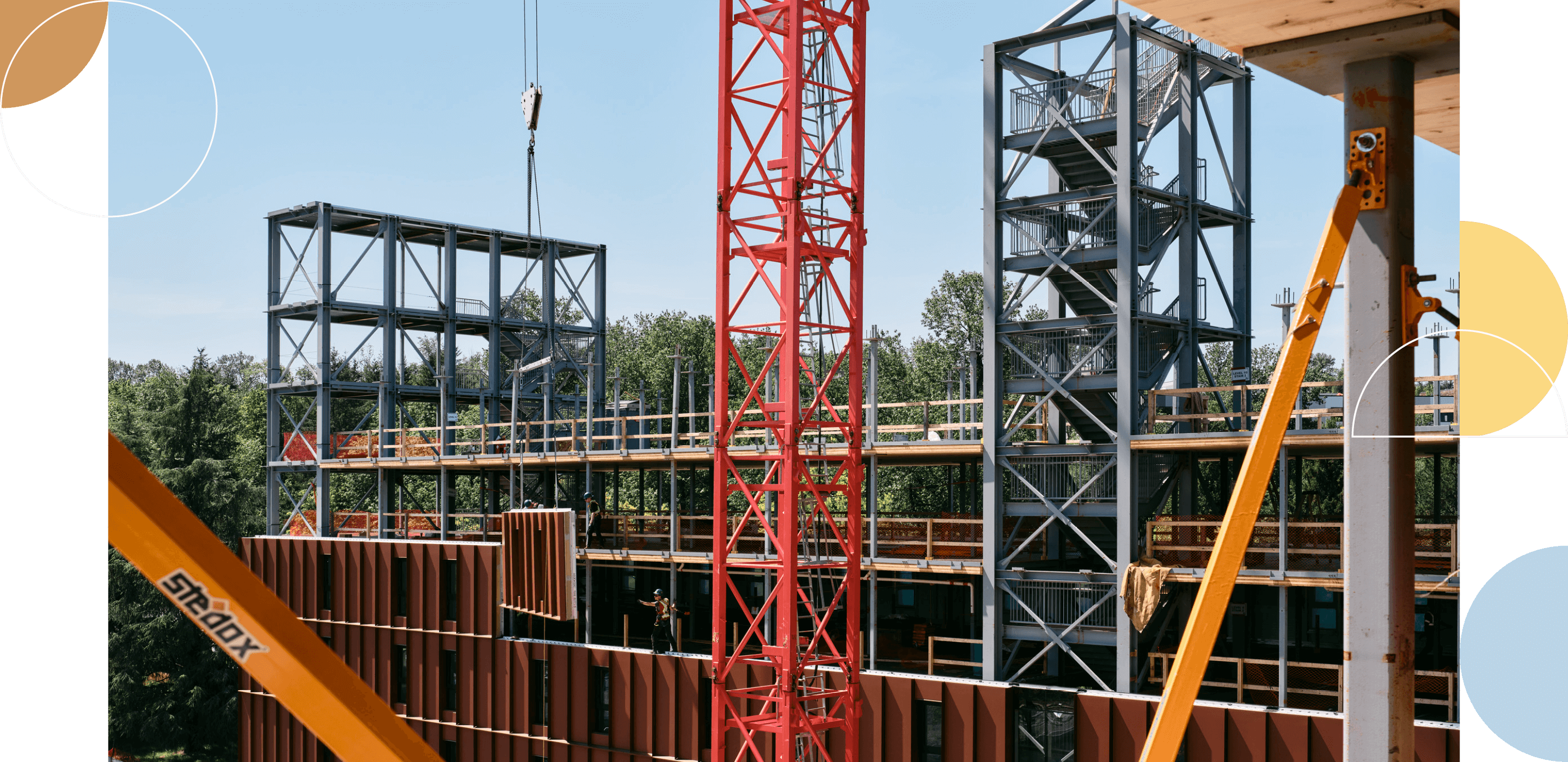

The 17,000-pound mass timber roof panels were constructed offsite and lifted into place via crane in a just-in-time delivery sequence. The resulting building meshes with the neighborhood’s mid-century aesthetic and its natural setting. “When thoughtful design harnesses the power of engineering, it evokes joy,” says Jaspreet Pahwa, DCPL’s director of capital planning and construction. “This building’s placement on the site is like a moment of poetry.”

The library has won numerous design awards, but Pahwa finds even more gratification in the public’s enthusiasm for its distinctive appearance. She recalls visiting a pop-up holiday bazaar where vendors were selling handmade art celebrating DC landmarks and local celebrities, like depictions of the Capitol, Supreme Court Justice Ruth Bader Ginsburg, and the Washington Monument. “It absolutely stopped me in my tracks when I saw an artist selling postcards with a watercolor rendition of the Southwest Library,” she says. “Something becomes iconic when it captures the public imagination, and this library has done that.”