Earlier this month you read about how we in the L.A. Studio decided to be part of the solution to the homelessness crisis in our county, where over 59,000 people are living without permanent shelter. After meeting with local service providers and touring as many of their facilities as we could, we came to recognize that a lot of the housing built for low-income and homeless populations is built with a triage mentality. We can definitely sympathize with this point of view. Resources are limited, and we all have a responsibility to use them in a way that provides shelter for the greatest number of people. But this is also the place where we saw the best opportunity to contribute. We believe that everyone should have a beautiful place to live. It’s our business to be inventive, solve problems, and create places based around user experience. This approach is what we’re trying to bring to housing and facilities that serve our most vulnerable L.A. residents.

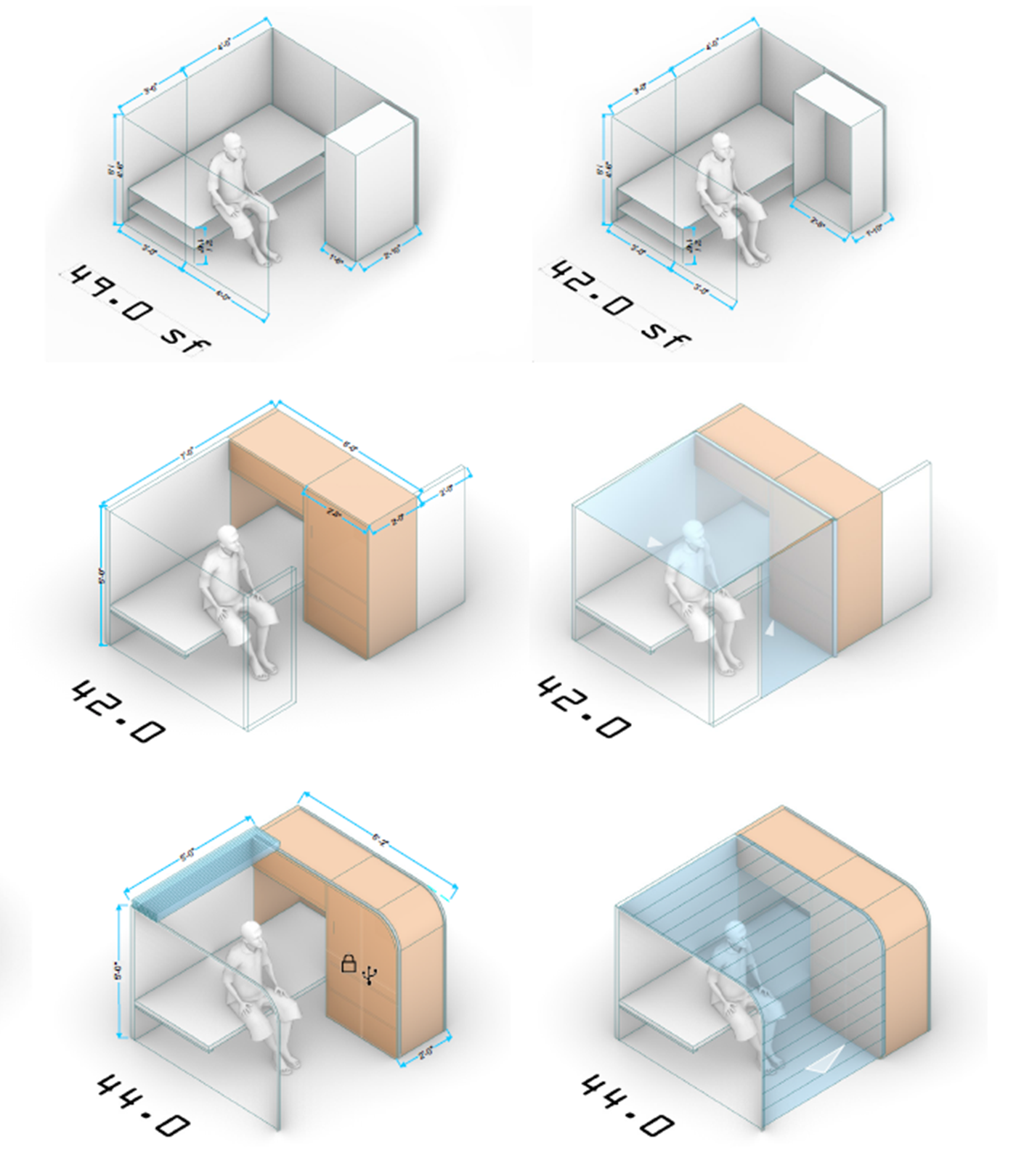

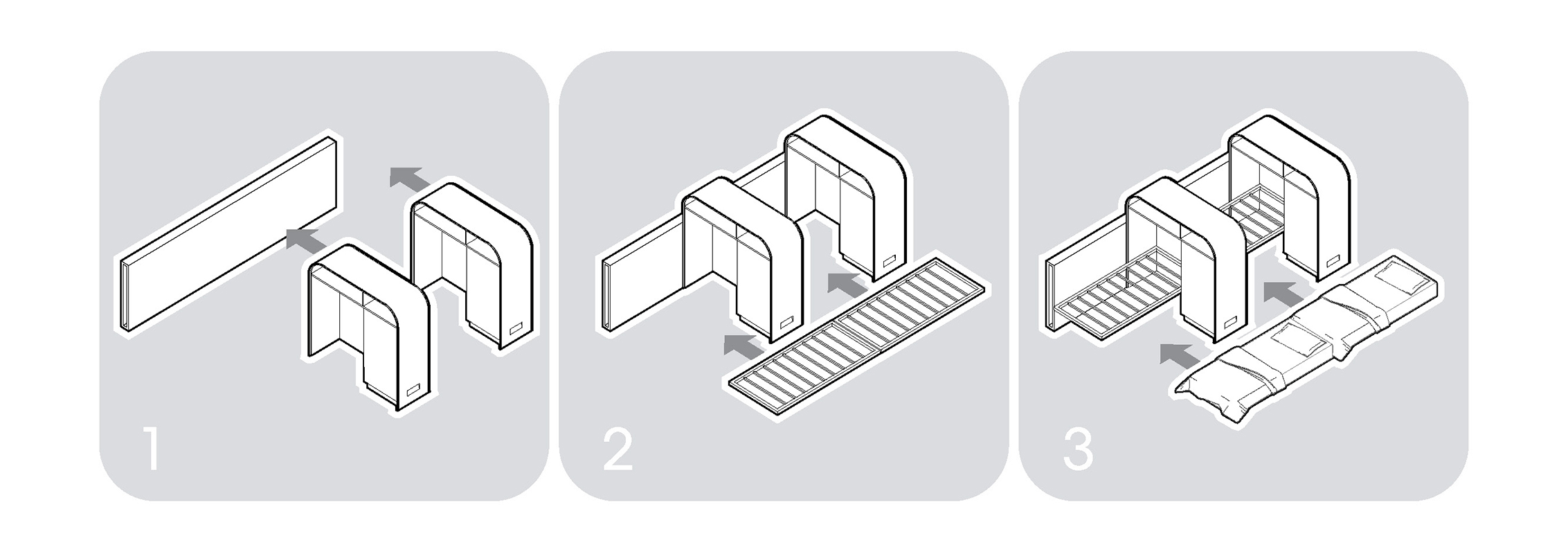

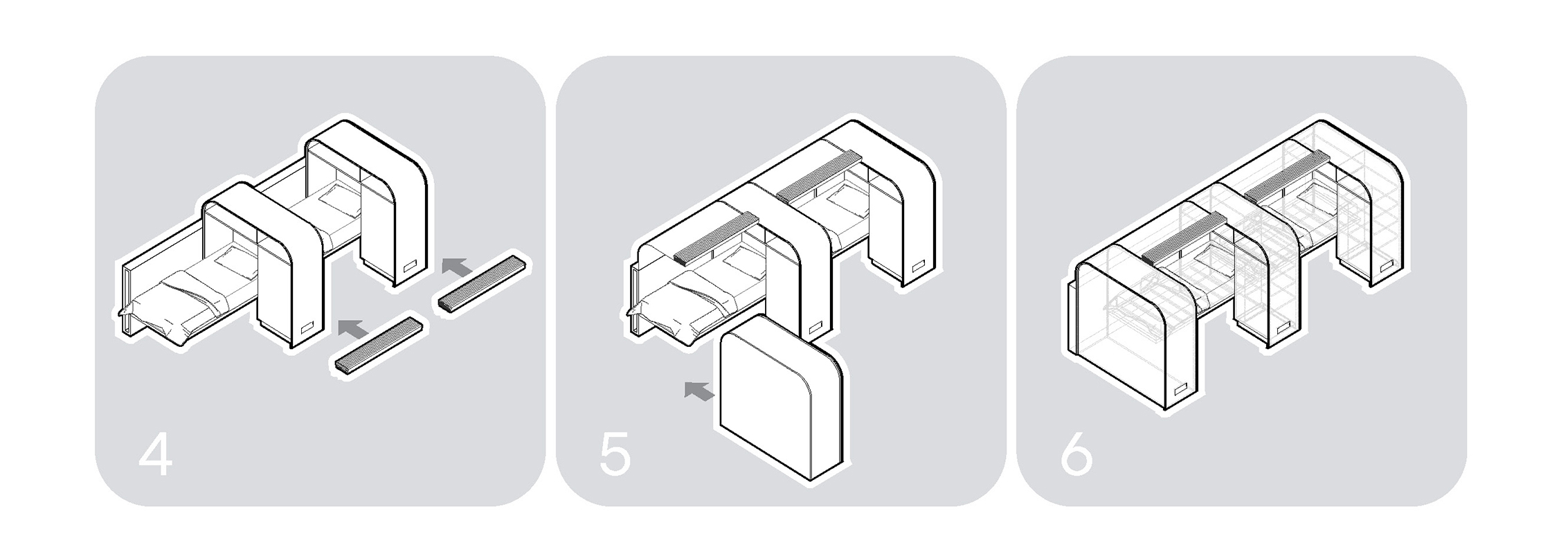

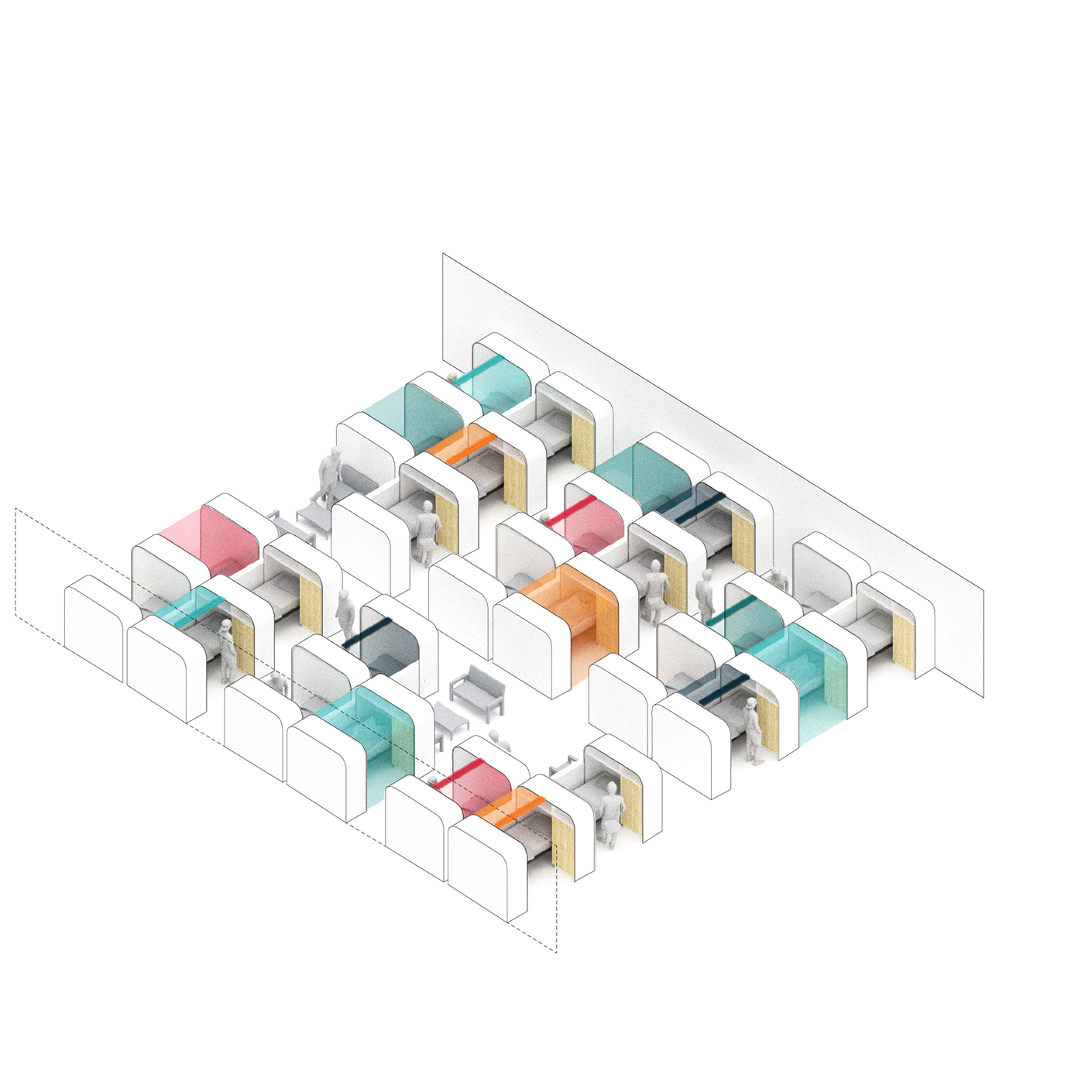

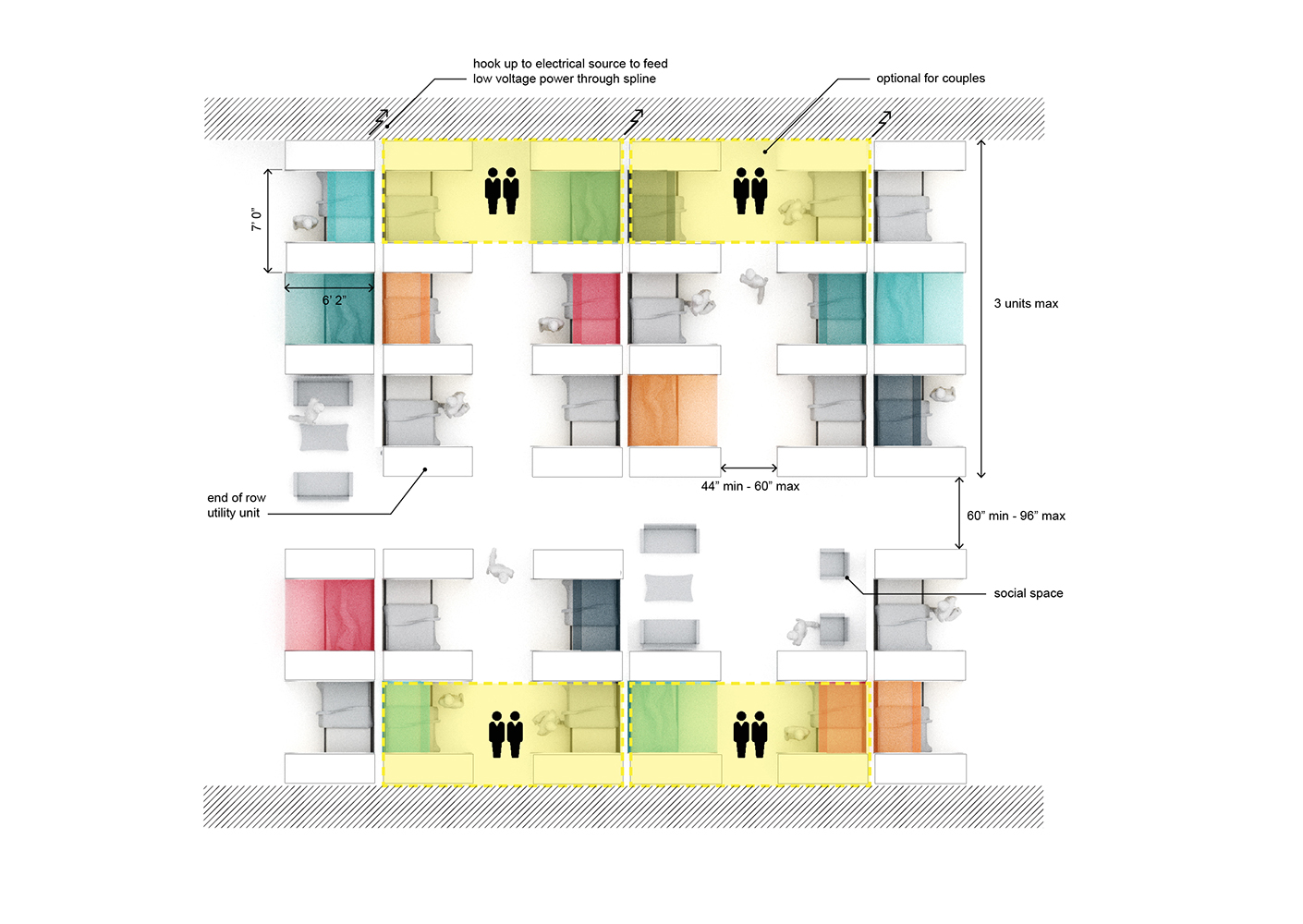

It didn’t take long to see that the wide range of conditions that are leaving people without a home requires an equally diverse suite of solutions. In response, our energy has been directed at innovation in housing—not just in prefabricated and new housing models like tiny-home villages, but also in furnishings. In next week’s post I’ll be detailing our role in what became the City’s A Bridge Home program, but this week I want to tell you about DOME, a modular sleeping unit we began working on after visiting several interim-housing facilities. I jump ahead because our team is at a critical point in the development of DOME, and the story of how we found ourselves designing a product is a window into how our approach to housing is evolving.