You mentioned our project with the University of Alabama in Huntsville, where their new Raymond B. Jones Engineering Building is underway and expected to open next year. You also touched on the connections between students and industry and, with Huntsville being a national hub of the aerospace industry, UAH is in a unique position. How is UAH’s new building supporting the aerospace program and what makes it interesting?

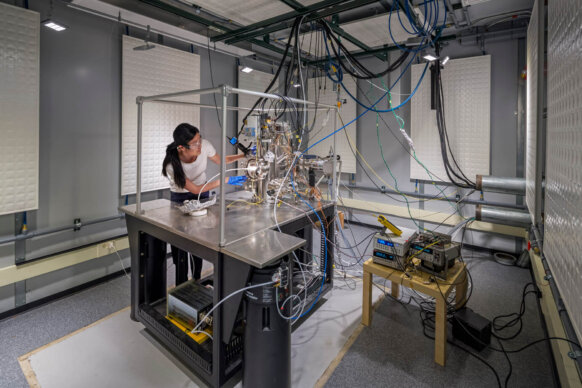

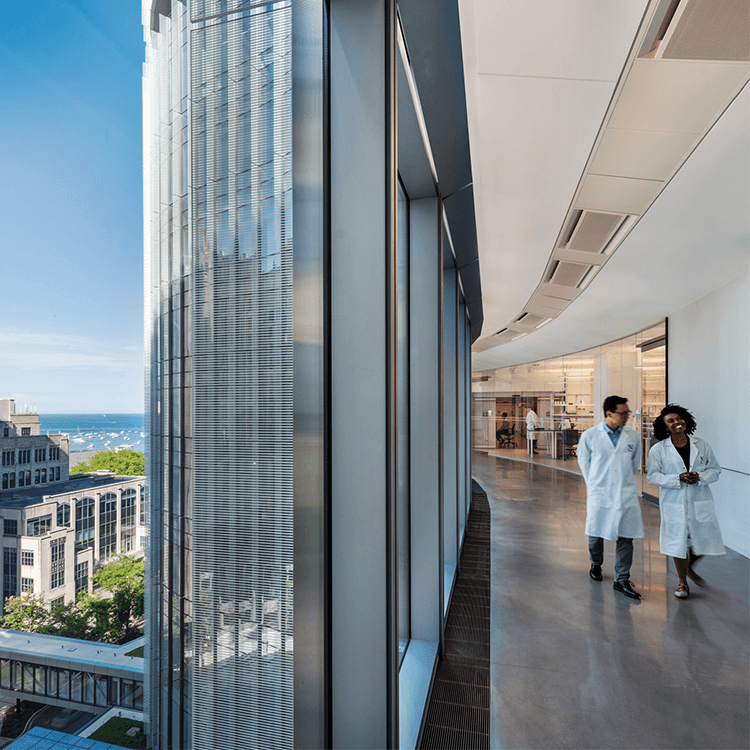

One of our mantras at UAH—and I believe a process we go through with all these colleges of engineering—is we want to design spaces that serve both research and teaching and are highly flexible. We know the technologies change quickly, so an ultimate philosophy of flexibility within UAH’s budget was critical.

UAH’s program is different in the sense that their College of Engineering is heavily weighted toward advanced degrees with many students in master’s or doctoral studies. That’s because the university supports the largest aerospace-focused research park in the U.S., Cummings Research Park. The park is literally across the street from the new engineering building. Our new building focuses on workforce training. The students are very connected to post-education practice, and the building reflects both the needs of UAH and the area industries.

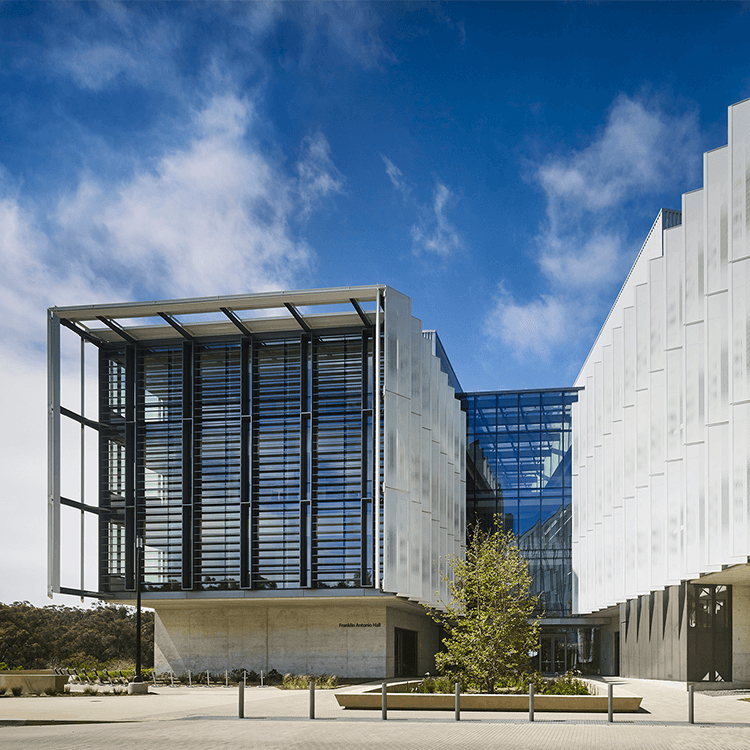

Before the UAH project was designed, the College of Engineering was housed in a 1960s-era building that didn’t adequately address the needs of the college, there were no spaces for the students to gather, study, or relax. Our project solves that, providing spaces for student breakout, for student clubs and activities, large gathering areas, hopefully a small food venue, visibility, and connectivity—all things the current College of Engineering building lacks. The design focuses on visibility and connections, and students will be able to see what’s happening around them and get excited about it. On top of that, our design, inside and out, honors the history of Huntsville, NASA Space Marshall Space Flight Center, and the Redstone Arsenal.

The second thing that’s unique is the link with Cummings Research Park and the amazing aerospace companies located in the park. There’s a strong desire by these aerospace companies to be involved in engineering education and to help craft the skills, programs, and classes they need for their engineers to be successful. The new building will draw industry to the campus, meaning these companies and the university both see it as a critical component of their success. The proximity at UAH is driving us to take it even further. Industry collaboration is very front and center. There are spaces in the new building for companies to work with students. It’s something we are intentional with in almost every single engineering building we’ve done.