Beautiful, resilient, and renewable, wood is quickly becoming a go-to material for future-ready construction. But with an array of timber products on the market, it can be overwhelming for designers to identify which material is best suited for their clients’ individual needs. “We often have a small window to make a product selection, and there’s rarely time to do extensive research to understand what’s available,” says Pratibha Chauhan, a planning and strategies consultant in our Minneapolis studio.

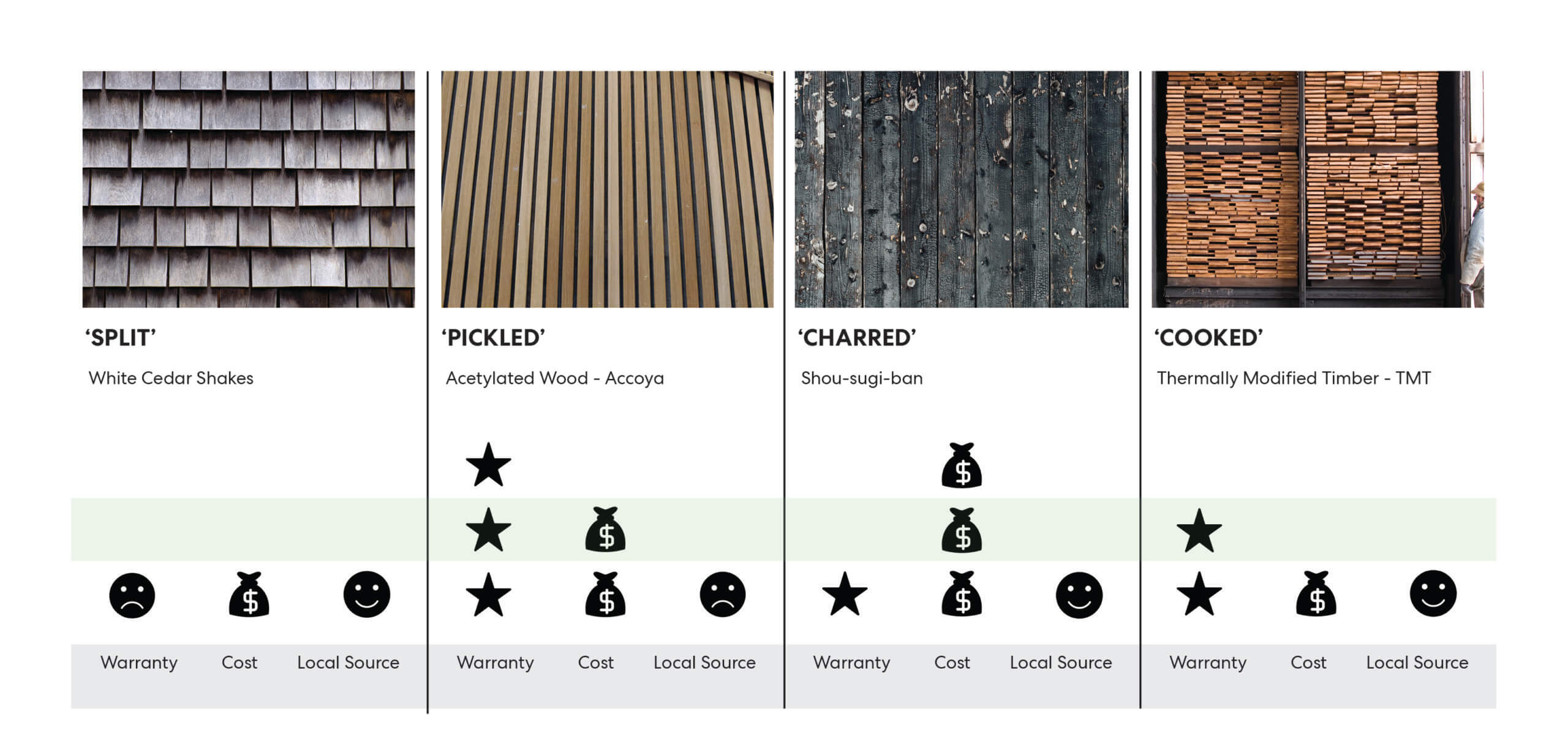

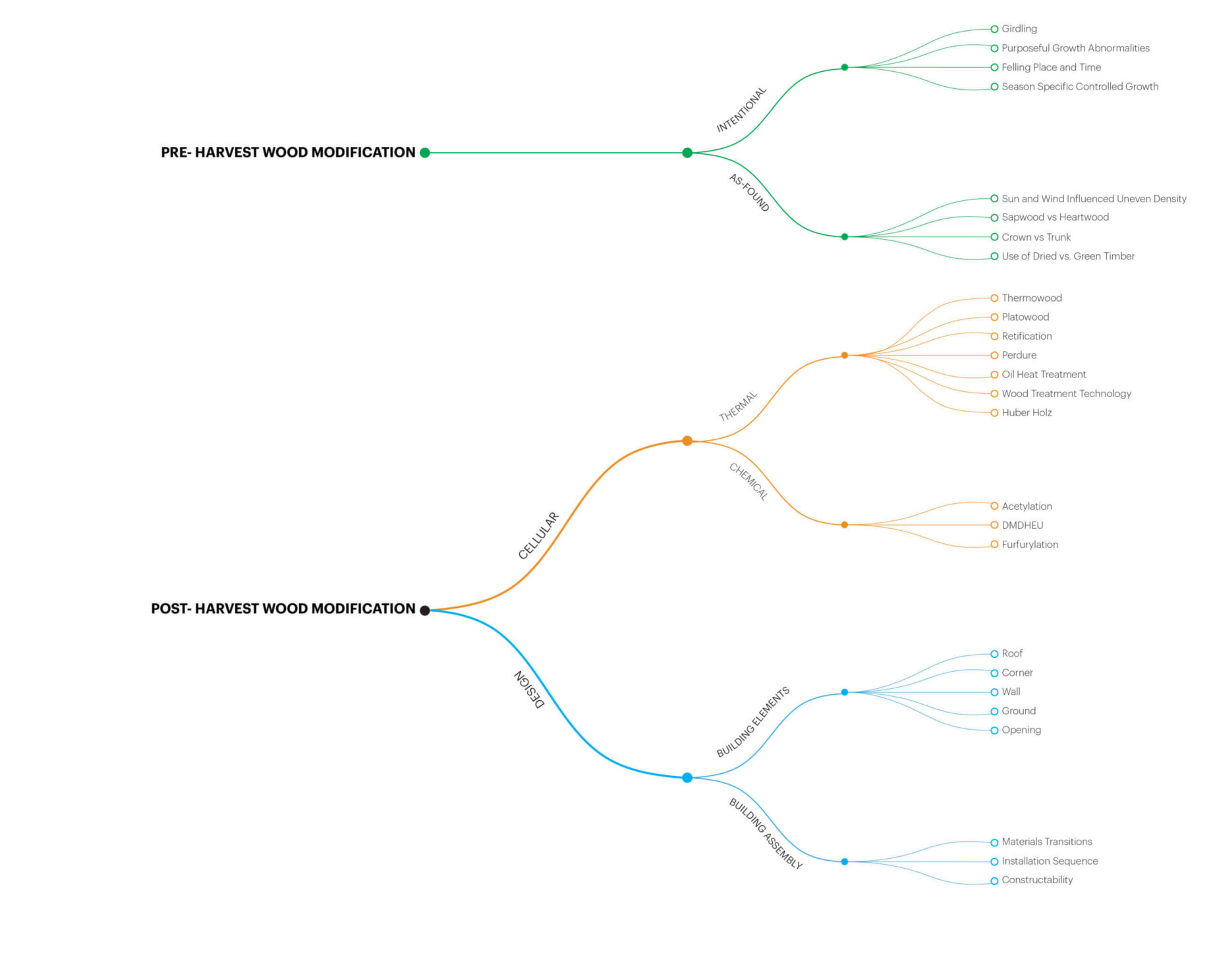

Fortunately, when the University of Minnesota Bell Museum sought our guidance on an exterior cladding product to meet their goals, Chauhan and the project team were able to do a deeper dive. They focused on a variety of timber modification processes, including white cedar shakes, wood acetylation, charred wood, and thermally modified timber (TMT), evaluating options based on cost, durability, source, warranty, and appearance. They landed on thermally modified eastern white pine—a species indigenous to Minnesota. Thermal treatment was selected for its ability to enhance the existing properties of the wood, increasing longevity and preventing decay.