“For hundreds of years, architects created physical drawings that served as instructions for others to carry out,” says Nick Cameron, director of digital practice at Perkins&Will. His team experiments with everything from immersive virtual reality (VR) and computational design to sensors that track and measure how people use their environments. “Today, robots and other technologies help us communicate better so we can bring the original intent of a design to life. Tomorrow, we’ll be able to get clients into even better versions of their finished spaces, even sooner.”

The use of digital tools in architecture dates to at least the 1970s, when prototypical computer-aided design (CAD) software was introduced. By the early aughts, 3D modeling—what’s often called BIM, or building information modeling—had become a staple, enabling the seamless integration of various structural, mechanical, electrical, and façade systems. More recently, it has evolved to allow for the automation of repetitive and time-consuming manual tasks.

“You can think of 3D modeling software as a kind of robot,” says Matt Petermann, a digital practice manager on Cameron’s team. “It streamlines workflows, shortens construction schedules, and gives project teams time for what they’re best at: being creative and following their intuition. Robots cannot replicate that. Not yet, at least!”

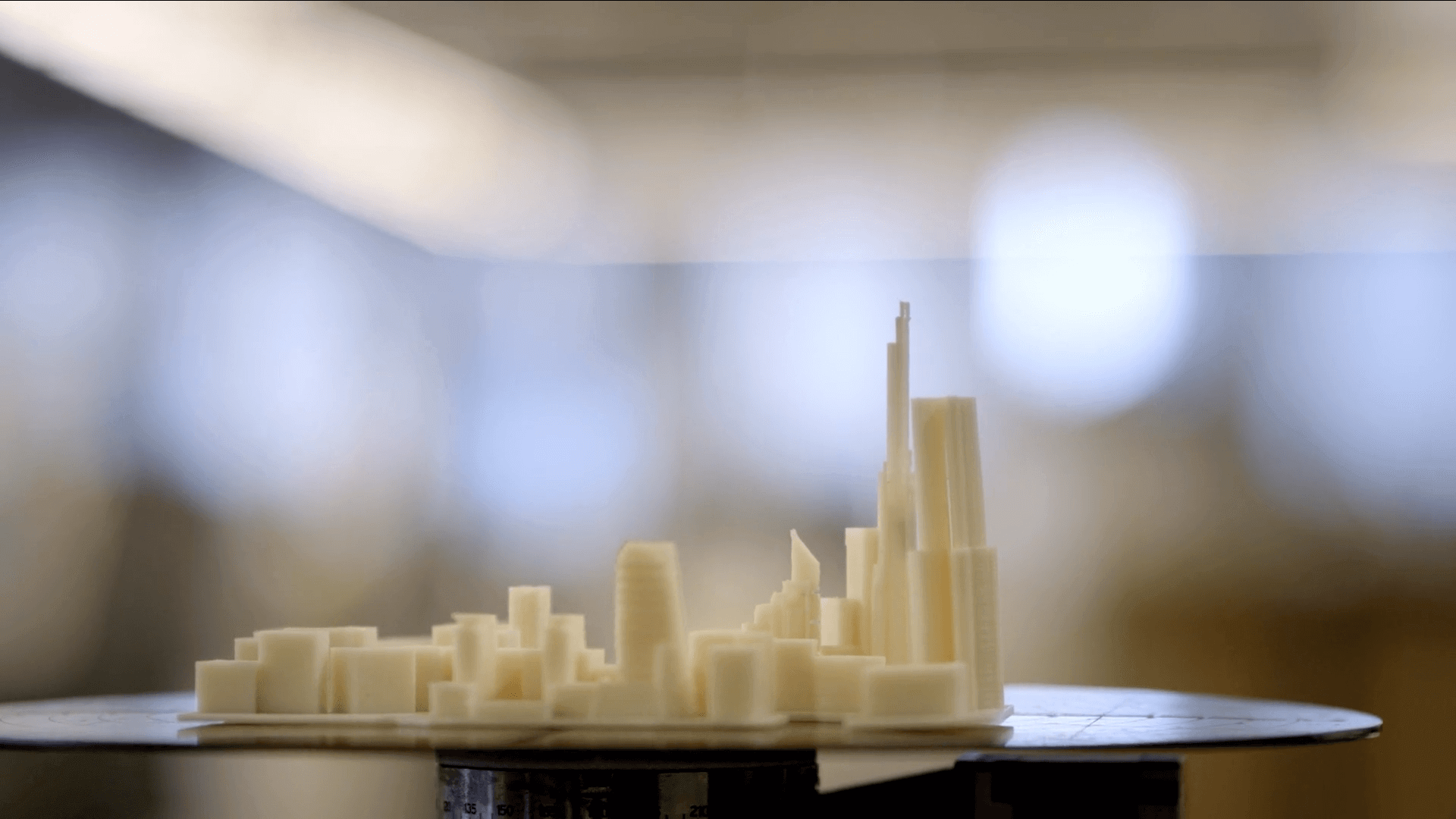

Robots may not be able to fully replace humans on design projects, but smart digital technologies that replace certain human tasks are gaining ground in architecture and construction in exciting new ways. Dexterous robotic arms that size and assemble intricate building components with precision are one example. Already, they’ve been used to construct life-size timber pavilions. 3D printers—think inkjet printers that apply additive layers of molten composite material to a surface until a three-dimensional form is created—are fashioning everything from public benches to single-family homes.