The world is facing a climate emergency. Last year alone, the UK produced 830 megatons of carbon dioxide, and we put 300 tonnes of fit out into landfill every day. The pandemic has helped push the sustainability agenda, but we have to take advantage of this momentum to effect lasting change over the coming years.

For instance, the UK Government has set clear sustainability targets for the built environment – an essential measure given that the built environment alone is responsible for 40 percent of the UK’s carbon emissions. By 2030, all new buildings must operate at net zero carbon. It can take 10 years for a building to go from design to construction, so these targets are directly relevant to the work we are all doing today. It is no longer a future problem.

Adam Strudwick, Principal of Corporate Interiors in our London studio team, joined Myriam Tryjefaczka, EMEA sustainability and public affairs director at Tarkett, in a live talk with Marcus Fairs, founder and editor-in-chief of Dezeen. The discussion centred on how manufacturers and architects can support circular design to contribute to the drive towards carbon neutral buildings.

Tarkett is a global leader in innovative flooring solutions. Asked how she would define the circular economy, Myriam explained that it is about “eliminating waste. We need to create an economy where waste does no longer exist, where materials are kept in constant circulation through a closed loop approach, and where they retain their value.” Tarkett’s conception of the circular economy goes further, in that it has to be healthy for both people and the environment.

Myriam summarised how Tarkett incorporates the circular economy into its work. As an “international player, and with the scale of an international player, we can drive force for change and make a positive impact.” They have two main objectives by 2030: to triple the recycled content of their products compared to 2018, and to reduce their carbon emissions by 30% in comparison to 2020.

For Tarkett, the starting point is eco-design, and using innovative Cradle-to-Cradle® principles as a guiding framework. They focus on ensuring that when their products reach end-of-life, the valuable materials they contain can be extracted as easily as possible, to be used again.

Myriam illustrated how they implement this in practice through ReStart, their take-back and recycling programme. Tarkett removes post-installation and used flooring, and provides occupiers with a certificate of the amount of material they have contributed. Between 2010 and 2019, they have collected 105,000 tonnes of flooring (post-installation and post-consumer vinyl, linoleum and carpet).

The real challenge, however, is how to recycle used flooring when it comes to the end of its life.

Tarkett has developed breakthrough technology to be in capacity to fully recycle carpet tiles and through a partnership with Aquafil. It is the only carpet-maker in Europe to have verified evidence of closing the loop on carpet tile production.

With regards to vinyl, often covered in glue, bits of concrete and other chemical residues from years of use, there are also important considerations about how to reintroduce used vinyl flooring into the supply chain with a complete safety guarantee. This is helped by Tarkett’s focus on eco-design from the beginning, for example using loose-lay solutions, but they have also developed innovative new technologies to clean and recycle shredded post-use vinyl. The benefits of this are stark. Every 1 tonne of vinyl recycled avoids 2 tonnes of carbon dioxide emissions.

At group level in 2019, Tarkett avoided 270,000 tonnes of carbon emissions due to the incorporation of recycled materials (yarn, vinyl, alternative plastics, fillers…), which represented more than the carbon dioxide emissions of all Tarkett factories that year, which emitted 240,000 tonnes.

However, Tarkett recognises that finding solutions to the hurdles they are still facing requires industry-wide collaboration. As a flooring manufacturer, Tarkett is involved in one aspect of construction, making it essential for them to have conversations at an early stage with all the key players in the development process about how to make more products circular and to encourage greater transparency across the supply chain.

Adam Strudwick began by commenting on how it is only relatively recently that we have seen a growing focus on the circular economy, and how the corporate interiors market is still behind. This was a driving force behind our recent pledge to deliver net zero interiors by 2030, which firmly puts circular design at its heart.

Adam explained how it is important to draw a distinction between operational and embodied carbon. While significant progress has been made in reducing operational carbon (the energy used to run a building), considerable challenges with embodied carbon (the carbon footprint) remain. This is where architects must focus, but to do so there needs to be collaboration with all those involved in the construction process.

There are several mindset shifts that have to occur for us to fully embrace circular design.

We have to start viewing buildings as material banks or storage vehicles for the future. Products and materials often have a longer lifespan than the space they are being used in, creating an obvious opportunity for reuse. Understanding this will lead to a radical shift in the construction methods and materials that designers will consider using. This will also encourage us to focus more on reuse rather than just recycling.

Adam used the example of fashion to show how are seeing a greater acceptance of second hand items in other industries, and how this could be suggestive of a shift in people’s views towards reused products.

Secondly, Adam explained that it is important to look at “designing for disassembly and that we consider reversible design.” We have to carefully examine which components of a building are underperforming from a circularity perspective, and find new ways of delivering that same level of performance. A good example of this, said Adam, is stud walls which cannot be moved without having to smash them down.

In the short term, this may lead to designers having to work with a smaller selection of materials while the supply chain catches up and starts to deliver truly circular products. However, this also creates an exciting opportunity to create a new design aesthetic.

Adam also explained how the circular economy can help address one of the major concerns for the fit-out industry – the standard commercial lease length. As end users demand greater flexibility, leases have become shorter. Given that this trend is set to continue, it is essential to approach design with a ‘circular’ mindset.

This is because at the heart of circular design is adaptability, which creates a clear synergy with business needs. If a building is adaptable, it will require less carbon to change it, meaning that a company’s future needs can be fulfilled, and in a sustainable way. Adam argues that this makes it easier to have important conversations about the circular economy with clients.

The need for adaptability has also been highlighted by the pandemic. The Excel conference centre, for example, was transformed into a hospital. We will also see a shift towards the conversion of office buildings into residential properties due to a lack of good quality affordable city-centre housing. However, these buildings have not been designed to be altered in this way. More adaptable designing means that buildings can be sustainably changed to react to whatever the market needs at that point in time.

Adam finished by echoing Myriam’s call for collaboration across the sector, discussing how Perkins&Will is focusing on supply chain engagement to ensure that their contractors and partners have the resources needed to meet their goals.

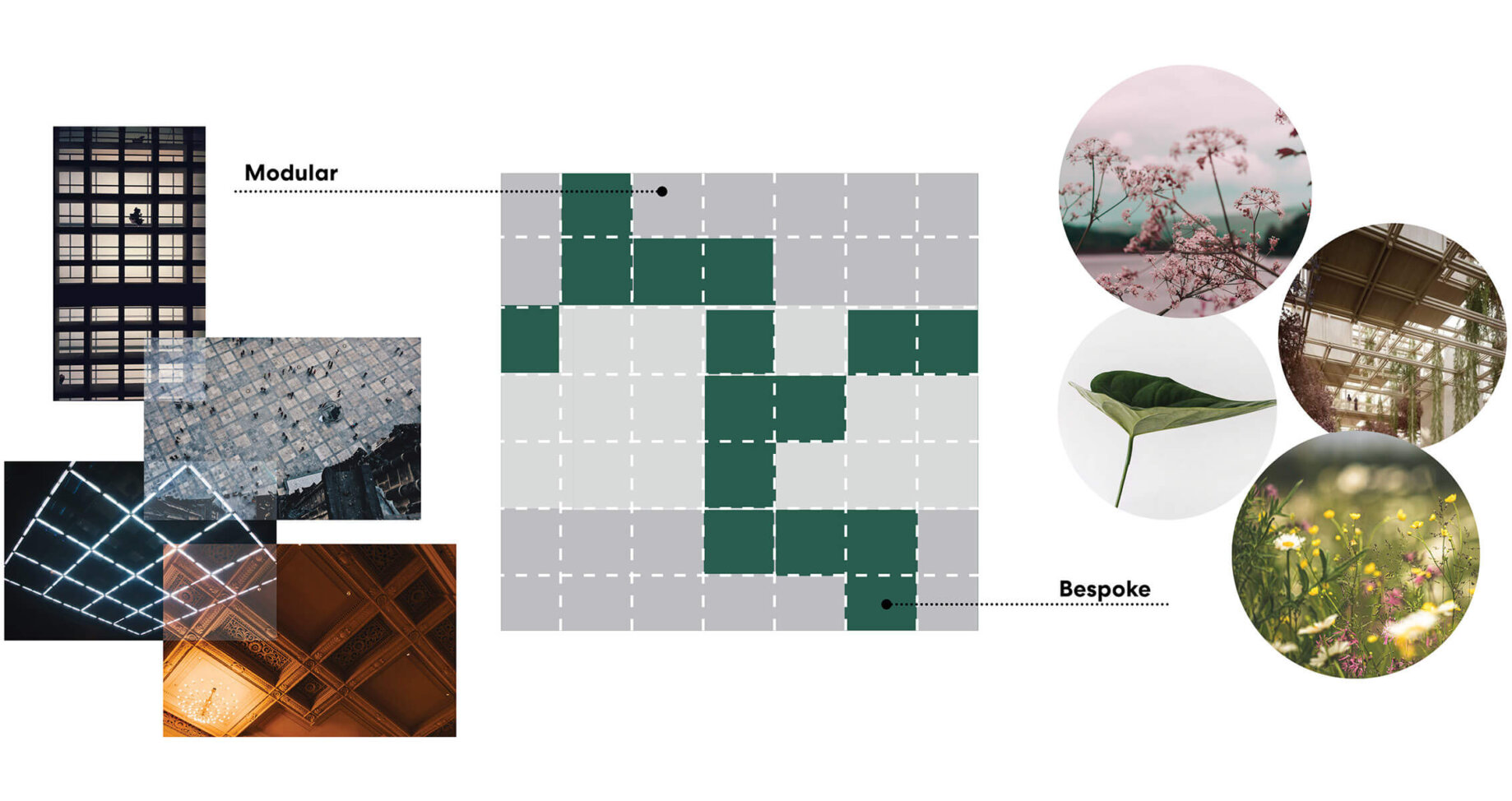

Asked by Marcus how the building of the future may look, Adam commented that we are likely to see an increased use of timber, at least in the short term, due to its ability to absorb carbon. Myriam suggested that we will see a greater use of modular products, such as modular flooring solutions which can support quicker renovations.

An attendee asked about the importance of education in promoting the circular economy and sustainable materials. Myriam commented that circular design is very new, which is why it is so essential for those across the industry to learn from each other and combat preconceptions. This led to an interesting conversation about the negative view of plastic. Myriam emphasised that plastic has a vital role to play in building and construction, particularly from a hygiene and technical perspective. Adam suggested that its reputation comes from problematic consumer single-use for packaging as an example. Yet there are many manufacturers, like Tarkett, who are expending considerable effort in improving their products so that they can be reused or recycled.

The conversation finished with a question as to what lessons about the circular economy can be applied from the built environment to other industries or the product design sector. Both Adam and Myriam highlighted the tension between linear consumerism model and sustainability endeavor and flagged the value that comes from sharing assets or materials.

This drew the live talk to a close with a fitting reference to a theme that came up throughout the discussion: collaboration. Myriam and Adam both talked about the importance of sharing learnings of the circular economy with those in the industry, to educate all those involved.

Circular design is an essential part of being able to achieve net-zero buildings by 2030, and to do this we need to encourage conversations, such as this one, between suppliers, architects, and developers.