In the face of the climate crisis, architects and designers have the responsibility to reduce the carbon impact of our built spaces. Looking beyond the carbon that stems from building operations, the carbon embedded in building materials, products, and systems contributes to environmental degradation and the warming of our planet. Known as “embodied carbon,” these emissions released during the lifecycle of building materials—from extraction to manufacturing to disposal—are responsible for 11% of total global emissions. However, not all projects are the same when it comes to embodied carbon impact. Interior renovation projects present a meaningful opportunity to tackle embodied carbon through smart and strategic design choices.

Why is the embodied carbon impact different in interiors?

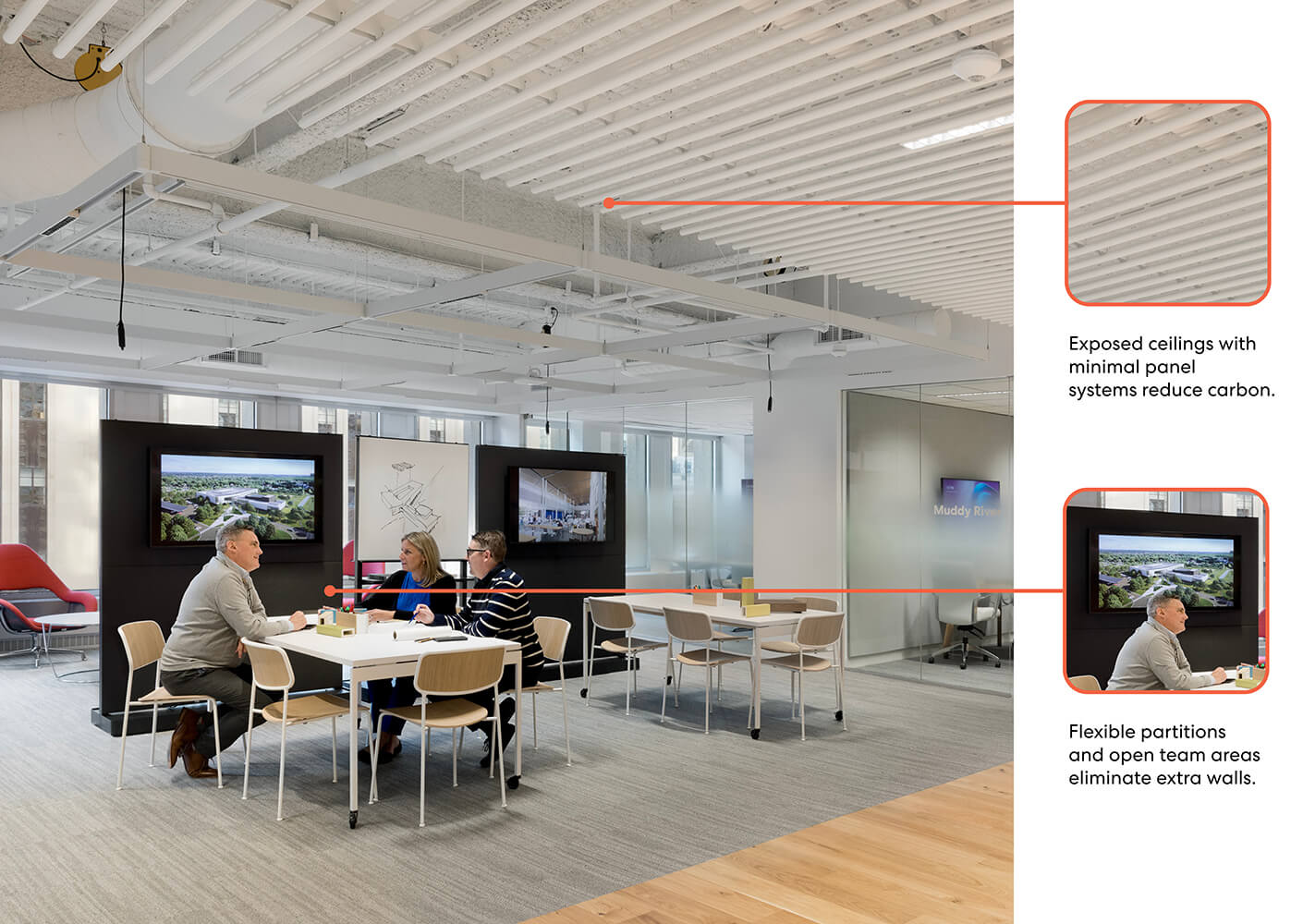

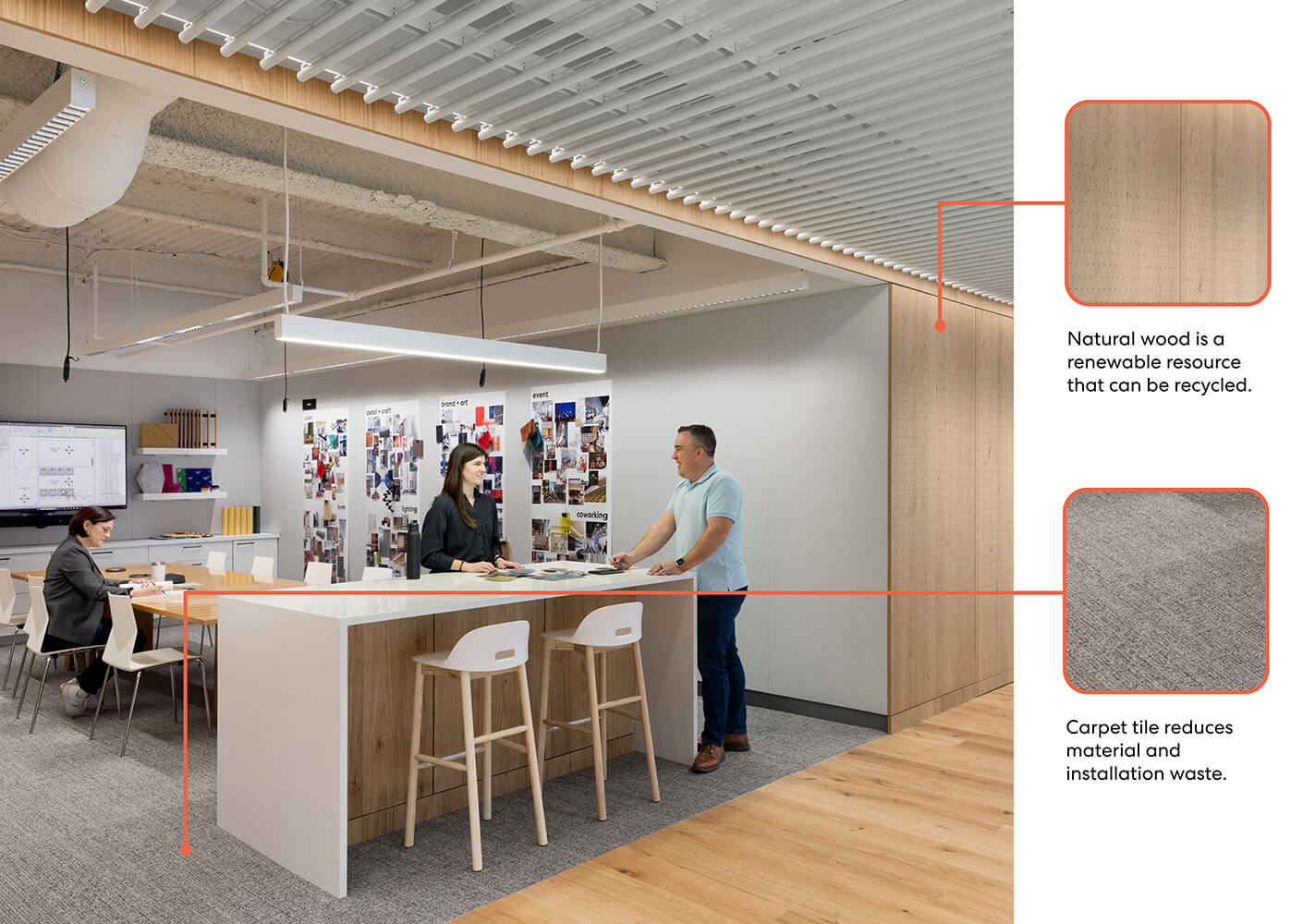

The cyclical nature of interior renovations creates an immense embodied carbon impact. Within office buildings, leases end, spaces fall vacant, and new tenants look to renovate every few years. While the typical lifespan of a core and shell office building is 50-60 years, interior spaces are often renovated every 8-10 years. As a result, the cumulative embodied carbon impact of multiple interior renovations can exceed initial core and shell construction. According to Carbon Leadership Forum, there are four interior product “hotspots” that have a striking impact: furniture, flooring, ceiling panel suspension systems, and walls.

In recognition of the significant carbon impact of our interior spaces, and in alignment with our Living Design Framework, Perkins&Will has pledged to achieve net zero embodied carbon office spaces by 2030. As we designed our new Boston Studio, we tackled embodied carbon head-on with several key reduction strategies and created a roadmap to shrink embodied carbon in interiors.