The popularity of using wood as a building material (beyond traditional stick-frame construction) has gained momentum in recent years. Where concrete, steel and a host of other materials have been typically used, advancements in design and manufacturing technology, changes to building codes, and a desire to integrate and demonstrate sustainability have all brought new uses for wood, from construction to finishing materials and even in new types of buildings. Wood’s unique properties enable a range of design innovations in structural engineering, aesthetics, and sustainability. Plus, using wood in construction facilitates greater speed and cost-effectiveness.

Perkins&Will have been early adopters of innovative uses of wood in design and construction. We developed a variety of wood “kit-of-parts” that integrate other building systems and accelerate project schedules, and we’ve long used mass timber products in building types where wood has not been traditionally used.

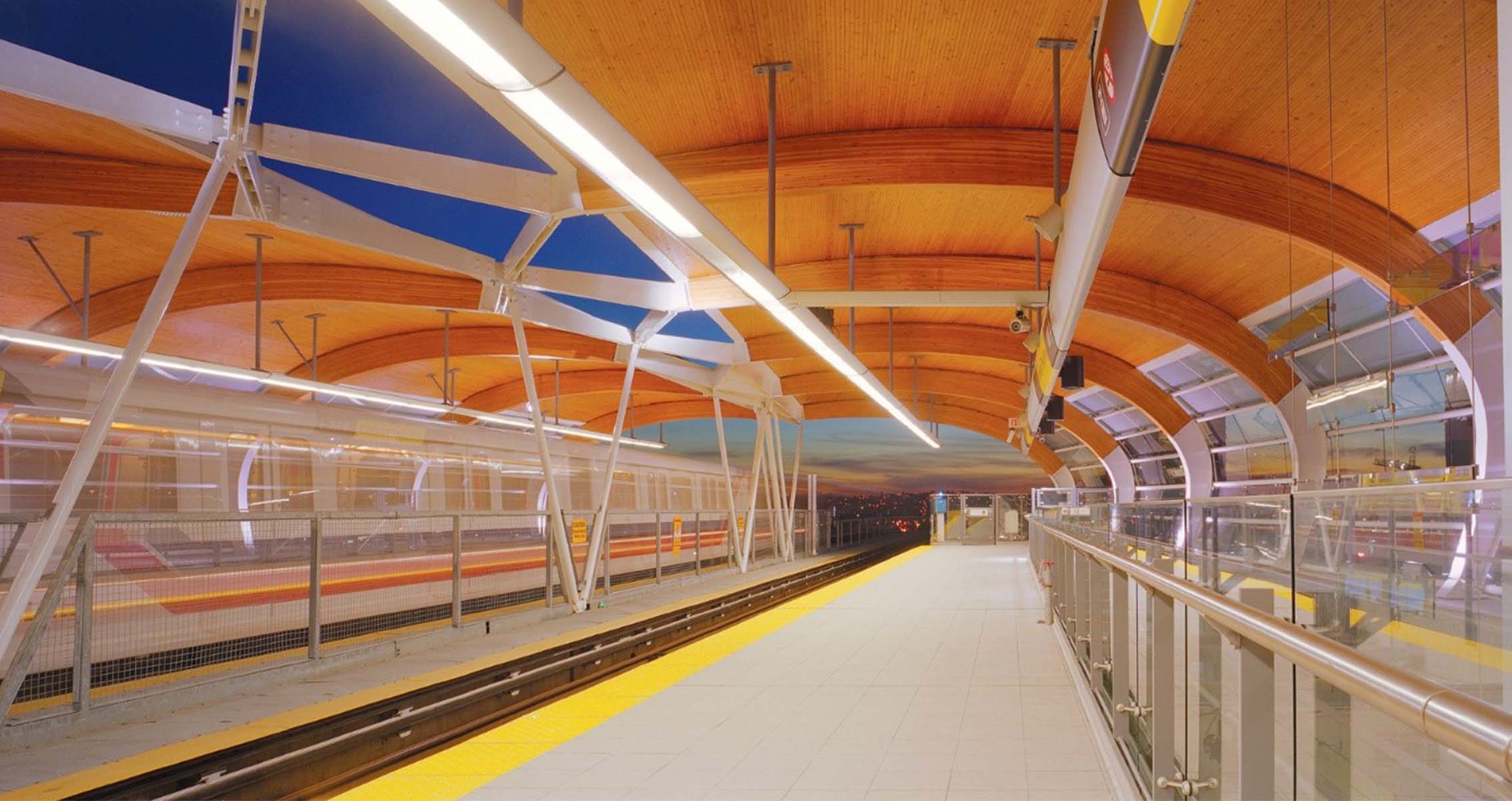

Vancouver’s regional transit system is a leading example of Perkins&Will’s legacy of wood innovation. Over the past 20 years, the firm has refined the use of wood over each subsequent system expansion, creating transit stations that capitalize on the multiple benefits of wood.

A Vision in Wood

In 1998, TransLink, Metro Vancouver’s regional transit provider, began the first expansion to its rapid rail SkyTrain network since the original development of the Expo Line twelve years before. As the authority began the process of building out what is now amongst the largest automated rail transit systems on Earth, they were aiming for a fresh identity for the new Millennium Line expansion and a way to demonstrate the importance and value of public transit to the region.

Working closely with structural engineer Fast + Epp, Perkins&Will advanced a bold vision centered around wood – a local, renewable resource representing billions of dollars to the local economy – as a signature element on the Brentwood and Gilmore Millennium Line stations. The move was a departure from the industrial aesthetic of the original Expo Line, and many of the other Millennium Line station designers followed suit, incorporating wood as a signature element. Wood continued to be incorporated in the subsequent Canada Line and Evergreen Line expansions, together creating a unique identity for Vancouver’s globally recognized transit system.

Prefabricated and modular design: a kit-of-parts approach

For Vancouver’s transit system, the integration of wood offered much more than a bold identity. Given its unique properties, the material was well suited to a modular approach to construction, allowing for components to be prefabricated off-site, reducing construction time which resulted in costs savings for the greater project. The modular wood roof components of both Millennium Line stations – Brentwood (arched glulam beams) and Gilmore (bent timber-strand panels) – were first-of-their-kind elements that set the stage for Perkins&Will’s systems-thinking approach to public transit facilities. Brentwood went on to become the region’s flagship station, winning international recognition and numerous awards including the Governor General of Canada Medal in Architecture.

Building on the design of the Millennium Line stations, Perkins&Will refined its kit-of-parts approach on the next system expansion – the Canada Line – completed ahead of schedule for Vancouver’s Winter Olympics in 2010. The firm developed a wing-form, prefabricated wooden structural roof system for the Aberdeen, Lansdowne, and Richmond-Brighouse Canada Line stations. The system integrated lighting, electrical and other services within each prefabricated module, and its success led to its mandated use on all elevated stations across the line by the design-build consortium leader.

In the region’s most recent extension, the Evergreen Line, Perkins&Will further refined the use of modular wood components in the design of the Lincoln and Burquitlam stations. The facilities incorporate an efficient and minimal building system with a warm, wood roof. As project budgets continued to shrink, Perkins&Will’s team was able to do a lot with a little, refining the modular wood roof elements and elegant detailing that contribute to the system’s signature aesthetic while delivering design excellence on time and budget.

Operational and maintenance cost savings

Wood also allows for cost savings in the operations and maintenance of transit facilities. Modular wooden components are easy and inexpensive to remove and replace. Moreover, the longevity of wood, when properly integrated and protected, contributes significantly to maintaining operations budgets over the life of a facility.

For example, the modular roof system developed by Perkins&Will and Fast + Epp for the Canada Line was made of standard lumber sizes found in any hardware store. These lumber beams were simply turned on end and dropped into a curved steel frame. By choosing this material and method of fabrication, the components are able to be accessed and replaced easily and cost-effectively, while contributing to the stunning aesthetic of the station environment.

Durable materials are another key factor in any busy public facility. The wood structural roof elements of Brentwood and Gilmore stations look as great today as they did over 17 years ago when the buildings opened to the public. According to TransLink, the facility’s owner and operator, they have not spent a single dollar on maintenance or replacement of any wood component of the roof systems in that same period.

Elevating the passenger experience

As the interface between people and infrastructure, station design is key to attracting and retaining ridership. The materials we choose for the finishes and structure of our public transit facilities greatly influence the quality of the passenger experience, thus affecting ridership. While everyone involved in the design, operations and maintenance of transit facilities understand the importance of material that is durable, flexible, and able to withstand public use in busy facilities, consideration must also be given to the experiential value of materials and their effect on health and well-being. By incorporating wood in transit stations, we are able to create a warm and inviting experience in these high-volume public buildings, and in turn, reduce stress for passengers and building users, while elevating the perception of the value of public investment in transit infrastructure.

A healthy, renewable and local resource

Building construction and operations represent a third of global production of greenhouse gas emissions. At the same time, the materials we use in our buildings directly affect the health of the people who occupy them. Employing wood as a primary element of a building can result in fewer emissions, a healthier environment for building users, and at the same time help sequester atmospheric carbon over the long term through the support of renewable forest practices. Employing a local and renewable resource like wood in public transit facilities is a strong emblem of a city’s or agency’s commitment to sustainable practices.

The future of wood in public transit

Perkins&Will’s early advocacy of integrated wood products and systems in public transit has influenced its success both locally and globally. The firm has since expanded this approach to bring the flexibility, cost-effectiveness, sustainability, and warmth of wood to systems across the firm’s global practice. With wood, we can build stations that deliver value for the public’s investment, and elevate and ennoble the passenger experience through warm, inviting, and elegant transit infrastructure. As we enter this new era of advancements in wood innovation, the use of wood will continue to evolve and be a viable and favorable material across applications and building types.