Shenzhen Energy Ring

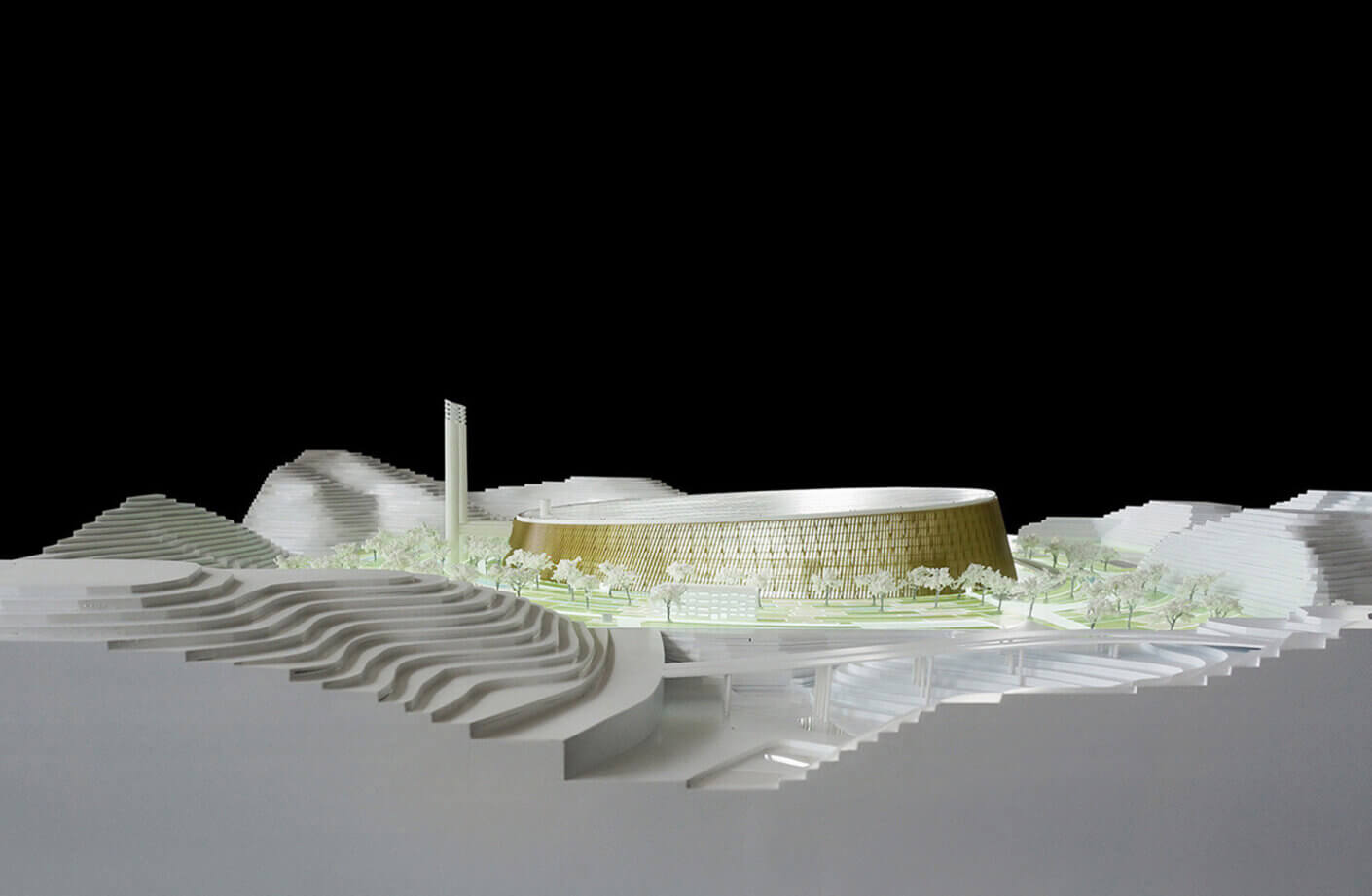

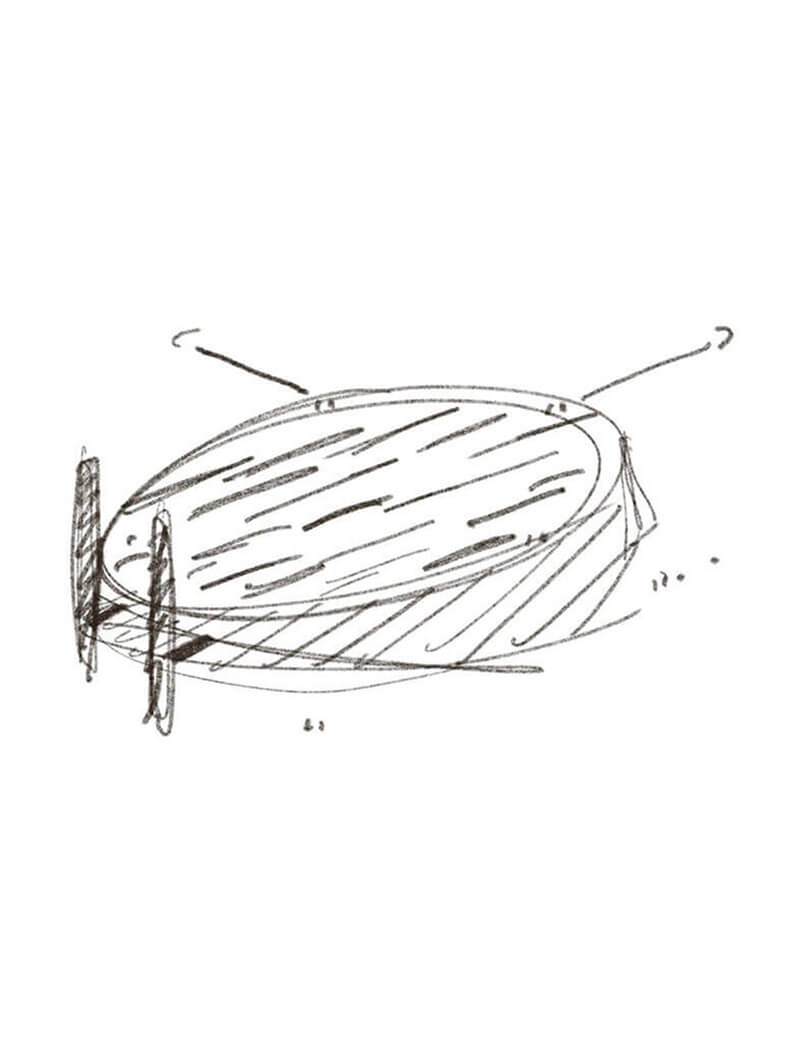

The urgency of the global climate crisis has given rise to a new type of architecture in China’s fastest-growing city: a waste-to-energy plant that doubles as an engaging community experience with facilities for research and development. The Shenzhen Energy Ring, designed by our Shanghai studio (Schmidt Hammer Lassen Architects) in collaboration with Gottlieb Paludan Architects, aims to set a new standard for environmentally progressive architecture by encapsulating a complex program in a simple, poetic form.

According to the World Bank, the global population generates more than two billion tons of municipal solid waste annually. Landfills also contribute nearly 19% of global methane emissions—a greenhouse gas that’s 80 times more powerful at warming the atmosphere than carbon dioxide. The Shenzhen Energy Ring will incinerate 5,000 tons of garbage per day, generating 1.2 billion kWh annually straight to the city’s energy grid.

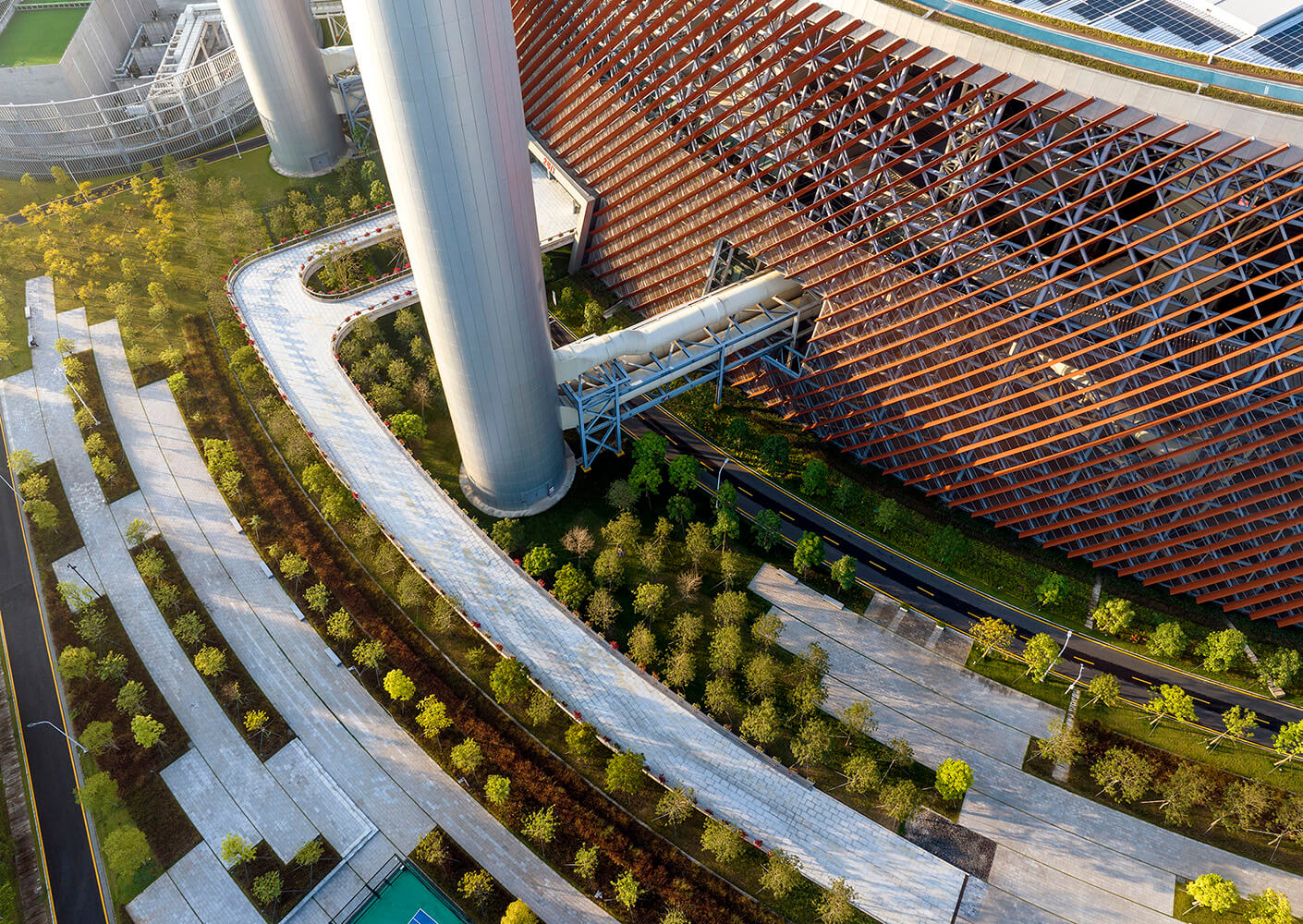

Visitors arrive at a plaza surrounded by landscaped gardens. A bridge leads into the building in a dramatic procession that passes between the plant’s two towering smokestacks. An information board at the entrance shows waste amounts processed and energy produced in real time.

The tour inside begins in a multi-floor exhibition hall where films and displays explain environmental issues. From there, a 150m-long elevated walkway enclosed in glass leads visitors through an in-depth look at the incineration process, from the waste bunker to the smoke treatment equipment.

A café at the end of the walkway gives visitors an opportunity for refreshment before boarding an elevator to the rooftop. There, a 1.1km footpath leads around the building’s perimeter, offering views of the solar installation and the surrounding hills.

After this immersion in heavy infrastructure, visitors pass through a garden of trees and flowers interspersed with sustainable-themed artwork. The experience is meant to provide a deeper understanding of the waste treatment processes and practical strategies for living more sustainably.

Central to the plant’s design is its innovative permeable envelope, which provides natural ventilation, smoke exhaust, and daylighting.

An assembly of 8,215 triangular-shaped steel lamellas wrap the building, spiraling up the facade. Burnt orange in color, the assembly is treated with a special coating that is pollution resistant and self-cleaning. Integral gutters drain the facade and expanded metal mesh controls access while allowing air to flow through the wall.

A steel louver system on the roof provides additional natural ventilation and daylighting while protecting the interior from the weather.

As one of the first industrial buildings in China to achieve LEED Gold, the design incorporates several ambitious sustainability features.

The plant’s emissions are well below the benchmarks set by both China and EU standards. The roof is fitted with an 18,000-square-meter photovoltaic array that generates approximately 3.6 million kWh of electricity annually, which feeds into the plant and the city’s electrical grid. The daylighting and natural ventilation strategies, which were specially tuned to Shenzhen’s sub-tropical climate, reduce the need for electric lighting and air conditioning.

The Energy Ring was also designed with future adaptive reuse in mind. As technology develops and Shenzhen’s needs change, the structure will remain relevant and useful for decades to come.

― Jiao Xianfeng, General Manager, Shenzhen Energy Environment Co., Ltd.

Shenzhen Energy Ring demonstrates that a high-performing energy plant can be just as beautiful, sculptural, and poetic as it is environmentally responsible. By anticipating future adaptive reuse and inviting the public to view its operations, it represents a new model of sustainability for waste-to-energy infrastructure.