Great Northern Way Office and Pavilion

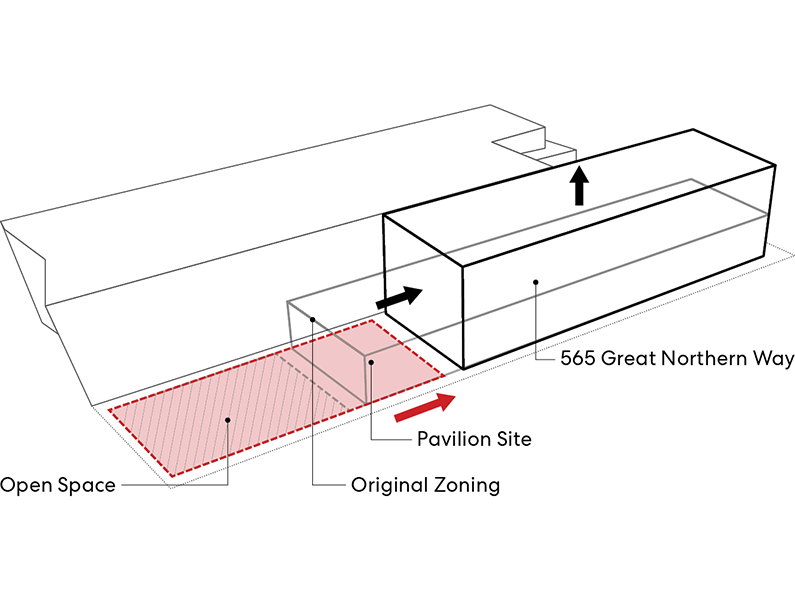

Seeing the potential in a long narrow parcel of land adjacent to the Emily Carr University of Art and Design in Vancouver’s False Creek Flats district, PCI Development Group approached us to develop a new office building with a public space for workers and students. Within this brief, we saw an opportunity. Redistributing density on the site unlocked access to the spectacular views of downtown Vancouver and the North Shore mountains while at the same time significantly expanding open space on site. The result is a generous and visible public realm—with an eye-catching retail pavilion at its centre—that has become both the front door and heart of a new creative district, and an elegant office building that is stitched into the fabric of the campus and the surrounding community.

― Emily Kaplun, Great Northern Way Trust

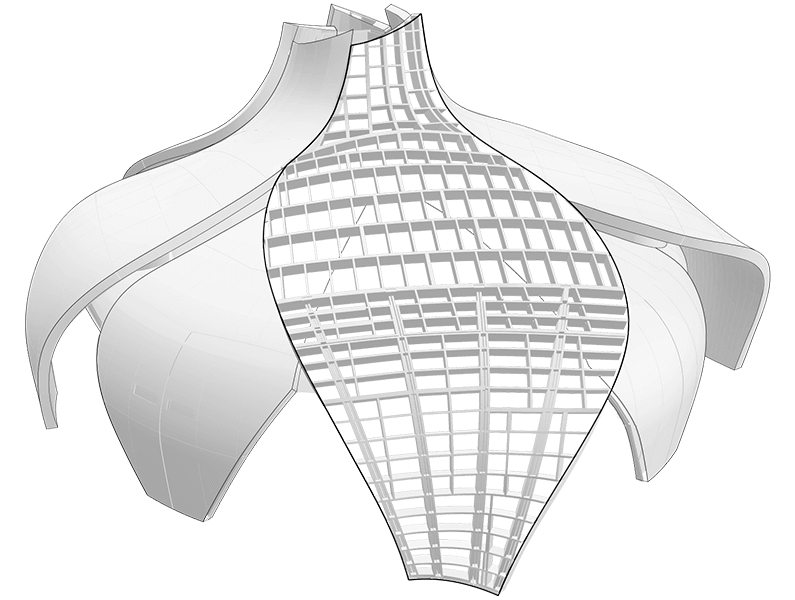

Working with the Great Northern Way Trust—whose mandate is to ensure the district is a vibrant and interesting place to work, study, and visit—we wanted our project to promote a sense of community and provide the all important link between digital media education and careers. The 1,850 square metre (20,000 square foot) large open space floorplates appeal to technology clients and allow for flexibility and adaptability. In turn these new tenants are positioned next to the institutions that will provide their talent pool of future innovators. Add to this a pavilion that is both a coffeehouse and a landmark sculptural building to anchor the regeneration of this district, and provide a much needed space for social connection, and you have a project that defines a new district.

Through material and fabrication research, and in collaboration with industry partners, the design team fabricated a complex curvature Nail Laminated Timber (NLT) structural panel as proof of concept. Learning from the prototype, the design team worked with the structural engineers and fabricators to optimize the petal forms, and develop a lighter and more cost effective structural solution. The CNC milled components required a digital workflow between the design team and fabricator. A shared model ensured a smooth and accurate process from design through fabrication.