New Heights Extend Mass Timber Efficiencies to New Building Types

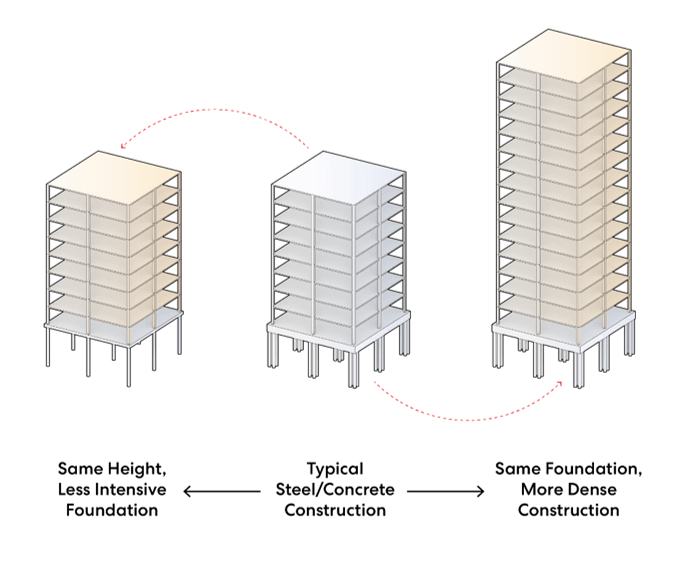

Previously limited to between four to six stories, multi-unit housing–including market- rate, below- market, and student housing product offerings in general–as well as construction of a range of building types in tight urban areas, will benefit the most from the new design possibilities of tall wood buildings. This difference of height, area, and density can make projects that don’t ‘pencil out’ from a schedule or cost perspective today, more viable for developers and owners after July. Oftentimes, the cost savings on the selection of a structural system aren’t derived from a direct comparison of the structural materials itself (mass timber vs. steel vs. concrete), but rather the large savings in foundation cost. Mass timber structures weigh significantly less and require foundations one half to one-third the size of their steel or concrete alternatives.

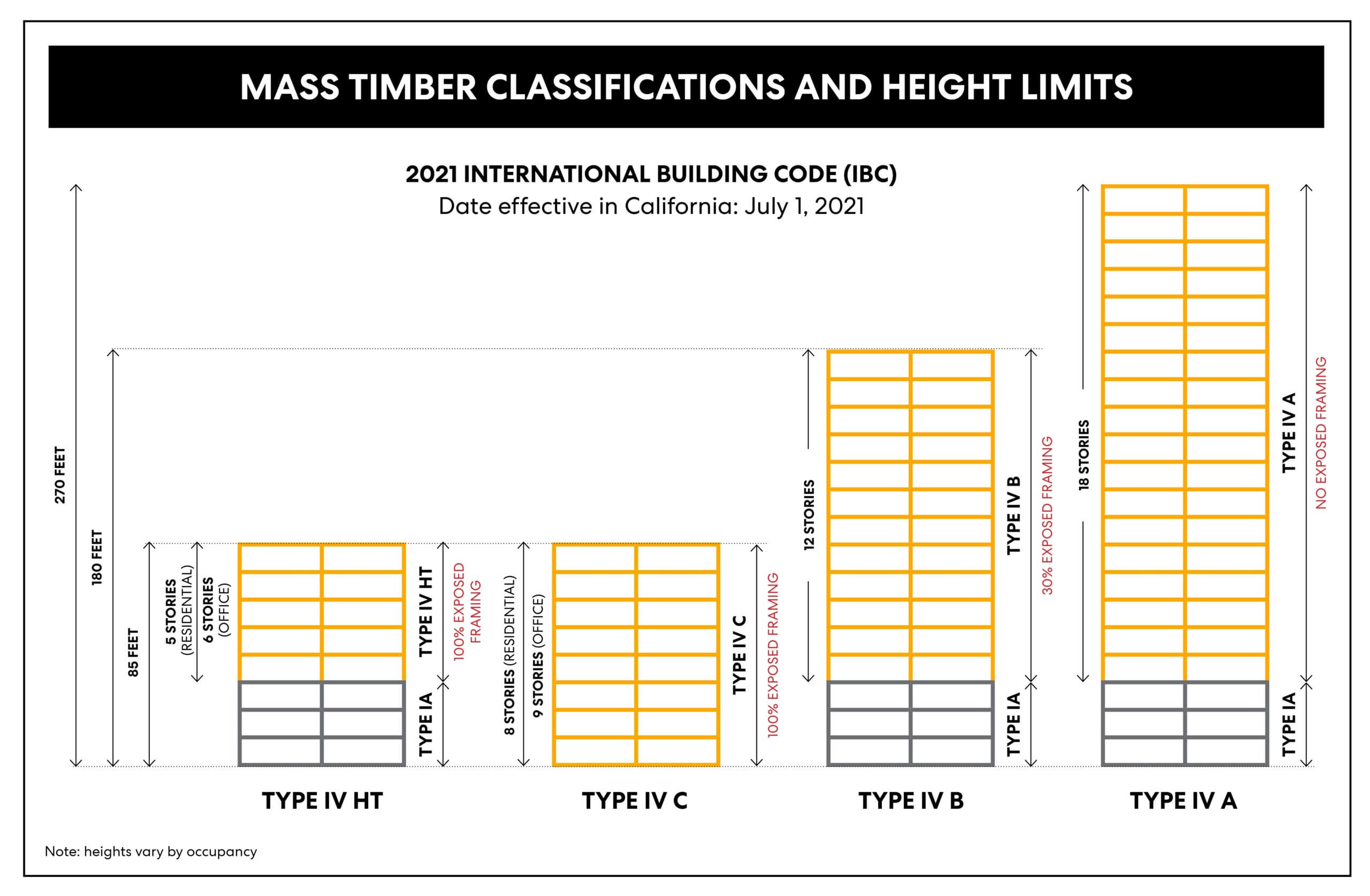

An R-2 occupancy multi-family housing project was previously limited to five stories, but, as of July, mass timber multi-family housing can be eight stories. The allowable area has also increased from 61,500 sf to 76,875 sf under the new category of Type IV-C. The new flexibilities translate to more units and more stories, yielding new advantages for the building owners who can now go taller and larger, while capitalizing on speed and efficiencies in mass timber construction.

Mass timber’s modularity and flexibility of scale across unit types is a key advantage of mass timber in multi-family or student housing. As unit sizes increase to include more bedrooms, the modularity of typical room sizes within the units and the mass timber slab widths allow critical alignments to scale up across unit sizes. These modular alignments mean there is a lot less material waste and labor in the field. Mass timber systems are predominantly prefabricated at an offset mill using precision CNC routers, so there is very close quality control around dimensional tolerances. Most mass timber systems have tolerances within 1/16”, which means the pieces fit together in a consistent and predictable way, with little variance from governing design dimensions. For housing projects, this is a critical distinction because accessible and adaptable clearances within units must be maintained once the final built elements are in place. Traditional concrete and steel projects have greater construction tolerances, and because of this, there are often dimensional variances in the final construction that require correction to meet code-required clearances. However, mass timber projects are able to maintain close control of construction outcomes in order to eliminate the need for corrections in the field. The precision also allows for better coordination with housing project trades, like mechanical, plumbing and electrical.

Construction of denser program types in constrained, urban areas can require a surgical approach. Mass timber’s logistical benefits bring an additional advantage beyond the material’s aesthetics. The modularity of these products streamline the on-site construction. As a tightly quality-controlled kit of parts, the mass timber structural panels arrive to the site sequentially organized on a flatbed truck so that the building can be assembled with a crane and a handful of workers–facilitating speed, accuracy, and predictable site logistics. This process allows increased control of construction cost and schedule which can be especially challenging on urban sites where unforeseen field corrections can be costly in time and materials.

When the contractor wraps up their work, the General Conditions savings from the months shaved off the project can be significant. Whether this translates to lease income from early occupancy or an extra semester of student residence; developers and contractors need to look at the project lifecycle to identify the savings, not just the construction costs.